Resource Circulation and Waste Reduction

Policy and Approach

We help conserve water resources by optimizing resource management and reducing water usage. Regarding raw materials, we will work to prioritize recyclable materials over petroleum-based raw materials and favor the selection of easy to recycle or reuse right from the product development stage, contributing to an efficient manufacturing process that generates little waste.

We will contribute to the establishment of a circular economy system by promoting cooperation with manufacturers, business partners, and local governments to ensure a smooth disposal process. We comply with the laws of each country in our manufacturing processes and utilize environmental management such as ISO 14001 to properly control and reduce pollutants.

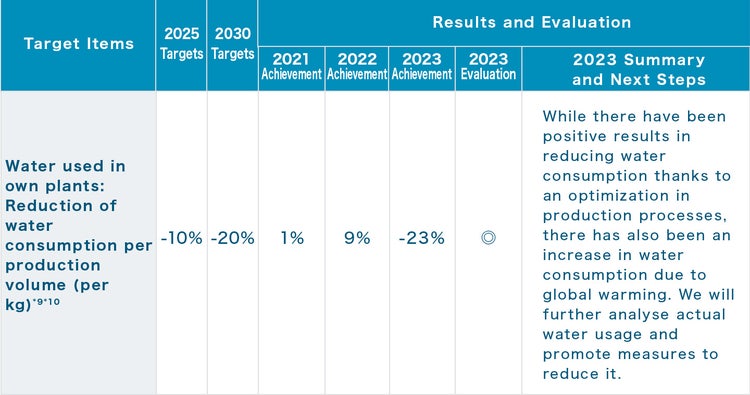

Mid- to Long-Term Environmental Targets and Results

* Scope of data:Data from group-owned global plants is integrated. Electricity, water and CO₂ are counted for the US Oral care plant, and electricity and CO₂ are counted for Tsubamex

Consumer Business = Oral care products, cosmetics, health foods, and other consumer product-related businesses

Industrial Business = Adhesives and sealants for automobiles, construction and electronics, and metal parts for motorcycles and automobiles

* Evaluation criteria: ◎ = Exceeds targets, ○ = Mostly on target, △ = Missed target but making progress, × = Worse than before

*9 Base year: 2020 for the Consumer Business, 2019 for the Industrial Business (because 2020 was a year of significant production cuts for the client companies)

*10 Excludes groundwater from the Yamanashi Plant and the Industrial Business

Major Initiatives

Used plastic collection and recycling (Japan)

In Japan, we began participating in an initiative in 2021 in collaboration with Kobe City and industry companies to collect toothbrushes and to present citizens with rulers made from recycled resin. In 2022, in collaboration with various industry companies, we began participating in a test program to collect and recycle refill packs for daily use products. Using trash bags made from recycled resin, we held community cleanup activities with local residents. We are working to create a system for resource recycling of used plastic products and packaging materials and to design products with low environmental impact.

Conducted a verification experiment to reduce packaging waste during product delivery (Japan)

We investigated using reusable folding containers to replace the cardboard cartons and plastic wrap used to prevent cargo collapse when transporting products between logistics centers. Moving forward, we aim to resolve remaining issues and implement their use in collaboration with related industries.

Recycling of waste plastic from the manufacturing process (Japan, Asia)

We are striving to reduce waste through resource recycling in plants. For example, we collect damaged plastic trays used in the Tokushima Plant for transporting products and recycle them into plastic trays for reuse. Plastic parts excluded from the toothbrush manufacturing process for failing to meet quality standards are also recycled into toothbrush stands and used as souvenirs for plant visitors. We have also launched an initiative at our Thai factory to collect PET bottles and caps for use as recycling materials.

Related partners